Effects & examples

related to Capillary

1. Effect: Capillary effect

2. Effect: Capillary pressure

3. Effect: Conic capillary effect

4. Effect: Capillary evaporation

5. Effect: Capillary evaporation rate radius dependence

6. Example: Capillary heat exchanger

7. Example: Condensation transporter using porous solid

8. Example: Electric contact using porous solid

9. Example: Extruder head using capillary-porous solid

10. Example: Fluid distribution via capillaries

11. Example: Glue roller using porous solid

12. Example: Heat transport system

13. Example: Humidifier using capillary-porous solid

14. Example: Liquid evaporator II

15. Example: Rotating shaft seal using porous elastic

16. Example: Writing instrument using porous solid

Description

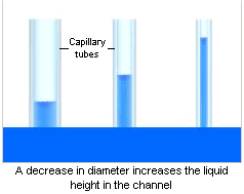

If a tube with a small diameter is immersed in liquid vertically with one end, the liquid in the tube will be either rise or descend some distance with regard to surface of the liquid. This effect is called as capillary effect and is a consequence of both surface tension and adhesion. Note that adhesive forces are attractive forces between molecules of different substances and hold different substances together (adhesion). Surface tension is determined by cohesion. Cohesive forces are attractive forces between molecules of substance and hold a substance together.

A surface force appear in the contact of different phases of a substance (solid-liquid-vapor, solid-liquid 1-liquid 2) at the phase interface. In so doing the force is directed towards one of the phases. The resultant force applied to the free surface of the liquid causes the surface to bend (occurrence of menisci) and changes the liquid level in the channel. The change value is determined by the condition of equality between the capillary pressure and weight of the liquid column in the channel.

See Also

Example: Heat pipe with longitudinal capillary structure

Example: Supply of coolant

Advantages

The capillary change in the liquid level occurs in the channels and clearances of any shape if the edge angle is not equal to 90°.

Effect Index

Effect is evaluated by a height of a liquid in a channel with regard to surface of the liquid.

![]()

h – height of a liquid column in a channel, m

q – limiting wetting angle, deg

s – coefficient of surface tension of liquid, N/m

r – channel radius, m

g – free fall acceleration, m/s2

r – liquid density, kg/m3

Materials

Formula

![]()

h – height of a liquid column in a channel, m

q – limiting wetting angle, deg

s – coefficient of surface tension of liquid, N/m

r – channel radius, m

g – free fall acceleration, m/s2

r – liquid density, kg/m3

Conditions

1. The liquid phase temperature is below the critical value.

2. The effect formula is valid at nonzero gravity.

References

Two-Phase Flow and Heat Transfer. Edited by D. Butterwarth and G.F. Hewitt, Oxford University Press, 1977.

Krumm. “Chip Cooling”. IBM Technical Disclosure Bulletin, 20, N7, Dec, 1977.

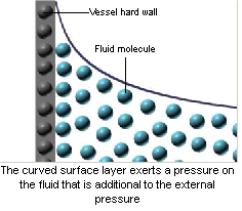

Description

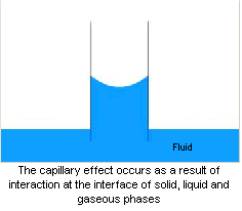

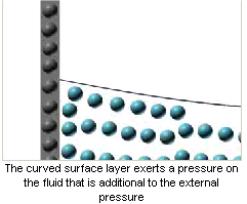

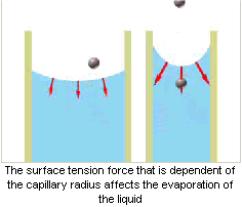

The surface of fluid put into a vessel has some curvature near the boundary of the fluid and the vessel hard wall. The curvature appears due to the interaction of the fluid and the solid molecules. If the vessel is narrow, the fluid total surface is not great. In this case, the walls influence the whole surface of the fluid. The surface appears to be curved all its way. The curved surface layer exerts a pressure on the fluid additional to the external pressure. The additional pressure is created by the surface tension forces. If the surface is convex, the excessive pressure P > 0. If the surface is concave, the excessive pressure P < 0.

Advantages

1. A method of the fluid surface tension measuring.

2. Manufacturing of fluid pumping devices.

Effect Index

![]()

h – fluid height in capillary, m

s – fluid

surface tension, N/m (Newton/m)

r – fluid density,

kg/m3

g – gravity acceleration, m/s2

R – capillary radius, m

Limitations

h ranges from 10-3 m to 1m.

Materials

For the majority of fluids under earth condition, h ranges from 1 to 5 mm, under the conditions of a space flight at the height of 300 km, h ranges from 0.4 to 1m.

Formula

![]()

P – capillary pressure, Pa

s – fluid surface tension, N/m

r – radius of surface curvature, m

Conditions

The fluid must retain its properties at the temperatures ranging from the freezing point to the boiling point.

References

Buyana, Theodore. Molecular Physics. Word Scientific, 1997

Kikoin, I.K. Molecular Physics (in Russian). Moscow: Physmatgiz, 1963.

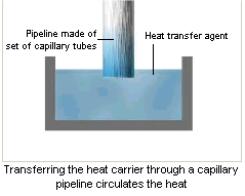

Example: Capillary heat exchanger

Description

The heat exchanger has chambers located one

above the other. Two pipelines

connect the chambers. One of the

pipelines sends the heat carrier from top to bottom. The other one conducts the carrier from the bottom

upwards. The second pipeline

comprises a set of capillary tubes.

The capillaries force the heat carrier to move from the lower container

to the upper one under capillary pressure.

Advantages

There are no mechanical friction elements.

Problem

In some heat exchangers, the heat carrier is forced to circulate by various pumps. This worsens the exchanger operating characteristics and complicates its structure as a whole.

Solution

In order to provide heat carrier circulation,

it is proposed to transfer the heat carrier through a capillary pipeline.

References

S.U. A.C. 648,825; Verdiev, et al.; Feb. 28, 1979; “Heat tube”; Dagestan Polytechnic Institute.

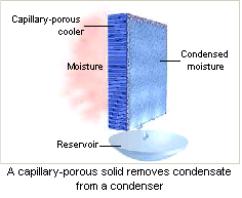

Example: Condensation transporter using porous solid

Description

A condenser made of a capillary-porous solid is used. When the condenser operates, a gas-vapor mixture is supplied to the condenser. The pores increase the surface area of contact with the mixture. Capillary forces transport the moisture condensed at the surface to a special reservoir.

Advantages

1. Continuous removal of condensed moisture from the condenser is possible.

2. No special equipment is needed.

3. The construction remains simple.

Problem

When a condenser operates, the produced moisture needs to be removed. The use of a pipeline system that has valves and vents complicates the construction as a whole.

Solution

In order to remove condensate from a condenser,

it is proposed to use a capillary-porous solid.

References

SU A.C. 769,273; Vassyliev, et al.; Nov. 7, 1980; “Condensator”; Lykov Institute of Heat and Mass Transfer.

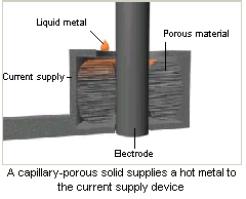

Example: Electric contact using porous solid

Description

The current supply device is made of a porous material. Then, it is filled with a hot metal. Under the capillary pressure, the porous material holds the hot metal and supplies it to the electric contact area.

Advantages

The electric contact is reliable and durable.

Problem

A device that supplies current to the electrode of an electric arc furnace uses hot metal. However, such a device has a complicated structure because of the necessity of sealing the body. Its contact has low reliability due to the great mobility of the hot metal.

Solution

In order to supply a hot metal into a current supply device,

it is proposed to use a capillary-porous solid.

References

SU A.C. 595,882; Frygin; Feb. 28, 1978; “Device supplying current to electric arc furnace electrode”; Kuibyshev Polytechnic Institute.

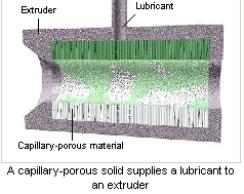

Example: Extruder head using capillary-porous solid

Description

The extruder working surface is made of a capillary porous material. Under the capillary pressure, the lubricant saturates the extruder porous working layer. Then the lubricant is proportionally distributed at the extruder surface.

Advantages

1. It is possible to continuously supply lubricant.

2. The lubricant is uniformly distributed onto the working surface of the extruder.

Problem

Processing of plastics and rubbers by pressure-die casting machines (extruders) requires continuous lubrication of the working surface. Conventional extruders that have special holes for lubricant supply under pressure do not provide uniform distribution of the lubricant on the working surface.

Solution

In order to supply a lubricant into an extruder,

it is proposed to use a capillary-porous solid.

References

SU A.C. 713,697; Sedlov, et al.; Feb. 5, 1980; “Extruder head.”

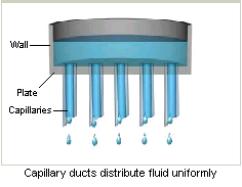

Example: Fluid distribution via capillaries

Description

Fluid distributing device consists of a grid, walls and pipes in the form of capillaries.

Capillary pressure provides for a constant liquid discharge head in capillaries. The liquid discharge head does not depend on fluctuation of its level over the capillaries. The fluid leaks evenly from capillaries and it is accumulated at their lower ends. Under gravity the drops of fluid detach from capillaries. All refluxing points operate uniformly irrespective of the fluid level fluctuation.

Advantages

1. The capillaries distribute fluid uniformly at small fluid flows.

2. The capillaries distribute fluid uniformly irrespective of the fluid level fluctuation.

Problem

Fluid in heat-and-mass exchange apparatus (for example, in packed columns) may be distributed with the help of grid with pipes fixed on it. When the grid deviates from the horizontal position and/or waves appear on the fluid surface, its level fluctuates over the ends of the pipes. As a result, fluid is unevenly distributed across the column cross-section area.

Solution

In order to distribute fluid uniformly,

it is proposed to distribute fluid via capillary duct.

References

SU A.C. 279,583; Alexeev, V.P.; et al.; Aug. 26, 1970; “Fluid distribution device”; Odessa Technological Institute of Food and Refrigeration Industry.

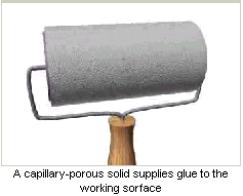

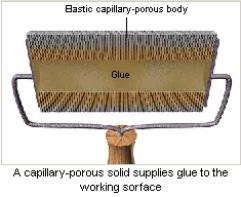

Example: Glue roller using porous solid

Description

The working surface of rollers for roll material gluing is made of an elastic porous solid. The glue contained inside the roller is supplied to the working surface by the capillary pressure.

Advantages

An elastic porous solid provides:

1. a roller that fits against the material to be rolled

2. continuous glue supply to the working surface

Problem

The majority of rollers for rolling glue have a gluing working surface made of a solid. As a result, the roller surface does not properly contact the uneven segments of the roll material. Also, the material needs to be periodically re-supplied with glue.

Solution

In order to supply a fluid glue to the gluing device surface,

it is proposed to use a capillary-porous solid.

References

SU A.C. 670,704; Belkov; Apr. 19, 1977; “Roller for roll material gluing.“

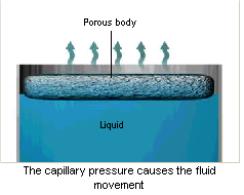

Example: Heat transport system

Description

A capillary-porous solid is used to supply a heat carrier. Being in contact with the fluid (a heat carrier) the capillary pressure makes the fluid rise and move along the capillaries to the working region of the heat transport system. The use of capillary pressure makes unnecessary compulsory fluid pumping devices. The effect provides the device working under a zero gravity.

Advantages

It is possible to use the heat transport system under a zero gravity.

Problem

In different heating devices, a compulsory pumping is used to create the heat carrier movement. The development of additional devices is necessary. This complicates the construction as a whole. In heating devices using no compulsory pumping, the gravity force is used to create the heat carrier movement. These devices cannot be used under a zero gravity.

Solution

In order to create the fluid movement,

it is proposed to use the capillary pressure.

References

U.S. Patent. 5,259,447; Ogushi, et al.; Nov. 9, 1993; “Heat transport system”; Mitsubishi Denki Kabushiki Kaisha, Tokyo, Japan.

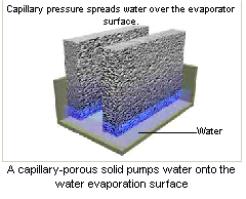

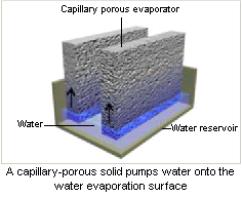

Example: Humidifier using capillary-porous solid

Description

The humidifier is made of a water reservoir and a set of capillary-porous evaporators. The bottom ends of the evaporators are placed below the water level. Under capillary pressure, the water rises from the reservoir and uniformly spreads throughout the evaporators and the evaporator surfaces. The capillary-porous evaporators have a large surface area from which water can evaporate. Thus the evaporation rate is increased. Also, the material directs a constant supply of water to its surface, so the process is continuous.

Advantages

1. Water is continuously supplied to the evaporator.

2. The device has no mechanical parts that would require power.

Problem

A powered pump is generally used to supply water from a humidifier reservoir to the evaporation region. In addition to consuming energy, the humidifier performance is not maximized.

Solution

In order to supply water onto the evaporator surface,

it is proposed to pump water by a capillary-porous solid.

References

U.S. Patent. 5,034,162; Chiu, et al.; Jul. 23, 1991; “High capacity portable humidifier”; Duracraft Corporation.

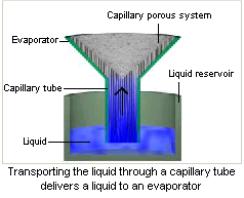

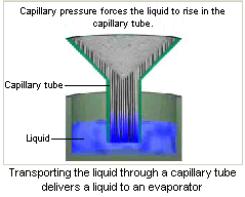

Description

The evaporation zone of an evaporator is connected to a liquid reservoir through a capillary tube. Under the capillary pressure, the liquid flows to the evaporator and gets distributed on the surface of a porous capillary structure. The porous capillary structure not only delivers the liquid to the evaporation zone but also substantially increases the free evaporation surface of the liquid.

Advantages

The system has no mechanical rubbing parts.

Problem

Liquids are forced to flow to the evaporation zone with the aid of various pumps. This has a negative effect on the functional quality of evaporators and complicates their construction.

Solution

In order to deliver a liquid to an evaporator,

it is proposed to transport the liquid through a capillary tube.

References

U.S. Patent. 5,558,720; Sarraf, et al.; Sep. 24,1996; “Rapid response vapor source”; Thermacure, Inc.; Pennsylvania State Research Foundation.

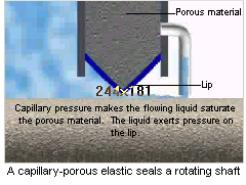

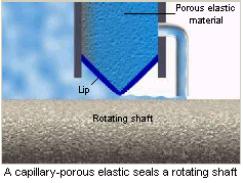

Example: Rotating shaft seal using porous elastic

Description

The internal part of the rotating shaft lip seal is made of a porous elastic. When the lip wears, the sealed liquid leaks. The leaking liquid comes into contact with the porous elastic material. Capillary pressure causes the liquid to saturate the material and create a pressure at the seal lip. As a result, the rotating shaft is hermetically sealed.

Advantages

1. The process is self-maintained.

2. The lip seal tightness improves.

Problem

In operation of a rotating shaft lip seal, the lip contact pressure decreases due to the lip wear. Also, the band spring deforms. As a result, the sealed liquid leakage increases.

Solution

In order to produce a hermetic sealing for a rotating shaft,

it is proposed to use a capillary-porous seal.

References

SU A.C. 1,010,366; Serbin, et al.; Apr. 7, 1983; “Running shaft lip seal”; Herson Industrial Institute.

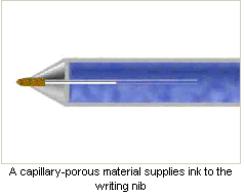

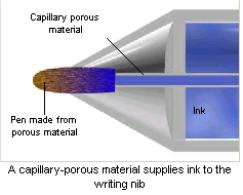

Example: Writing instrument using porous solid

Description

The writing instrument ink reservoir and the nib are connected through a capillary-porous solid. Capillary pressure supplies ink to the nib. The nib is also made of a porous solid.

Advantages

Ink is continuously supplied, regardless of the position of the writing implement.

Problem

In a majority of writing instruments, ink is supplied to the nib by gravity. The writing instruments operate by a direct contact between the nib and the ink. These instruments do not operate in the absence of gravity, upside-down, or when the ink and nib contact is disrupted.

Solution

In order to supply ink to the writing instrument nib,

it is proposed to use a capillary-porous solid.

References

U.S. Patent. 5,556,215; Hori, Jiro; Sep. 17, 1996; “Writing instrument with overflow chamber.”

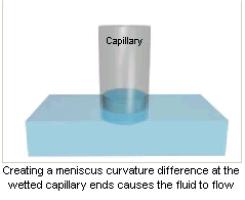

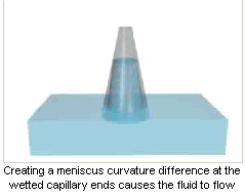

Effect: Conic capillary effect

Description

The meniscus in a capillary creates a capillary pressure. The value of this pressure is directly proportional to the meniscus curvature. If a capillary section is filled with the fluid, menisci are formed at the liquid section ends. If these menisci have different curvatures (e. g. a capillary has a conic shape or its wettability varies to its length), a capillary pressure difference occurs between the liquid section ends. Under the influence of this difference the fluid will flow in the direction of a meniscus having a larger curvature.

See Also

Example: Capillary heat pipe

Advantages

1. A pressure differential occurs both in the wetting and nonwetting fluids.

2. The fluid flows in a capillary of variable dimensions, or with variable wettability.

Effect Index

![]()

DP – pressure differential between the wetted capillary ends, N/m2

r1 and r 2 – meniscus radii at the capillary ends, m

s – surface tension coefficient of the fluid, N/m

Limitations

DP can change from a zero pressure determined by the thinnest section of a capillary.

Materials

The pressure drop depends upon the fluid, capillary dimensions and dimension variations to the capillary length.

Formula

![]()

DP – pressure differential between the wetted capillary ends, N/m2

r1 and r 2 – meniscus radii at the capillary ends, m

s – surface tension coefficient of the fluid, N/m

Conditions

The capillary must have either unidimensional, or bidimensional menisci of the fluid.

References

Heat Exchanger Design Handbook, Hemisphere Publishing Corp., 3 (1983).

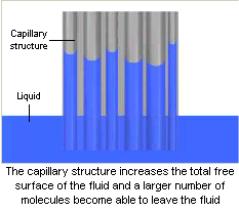

Description

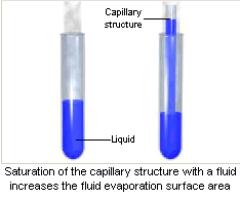

The fluid evaporation intensity depends upon the free surface area, as a larger number of molecules are able to leave the fluid. One of the means to increase the free surface of the fluid is to give it a possibility to fill the capillary structure. Thus, the free surface of the fluid in the vessel is added with the surface of the fluid which is in the capillary structure. The fluid propagates along the capillaries under the influence of surface forces until they are balanced by the gravitational force of the raised fluid.

See Also

Example: Desalinating installation with capillary evaporator

Example: Humidifier

Example: Liquid evaporator I

Advantages

The fluid propagates along the capillaries under the influence of surface forces until they are balanced by the gravitational force of the raised fluid. It determines limitations on a degree of increase of the evaporation surface.

Effect Index

![]()

n – effect index

S – free area of the liquid in the vessel

S0– free area of the liquid in the capillary structure and in the vessel

Formula

![]()

S – evaporation surface area

r – characteristic capillary radius

X – characteristic dimensions of the capillary structure

s – fluid properties

Conditions

1. The fluid must wet the capillary structure material.

2. The pores of the capillary structure material must be open.

References

Swartz C.E., Phenomenal Physics, John Wiley & Sons, New York 1981.

Effect: Capillary evaporation rate radius dependence

Description

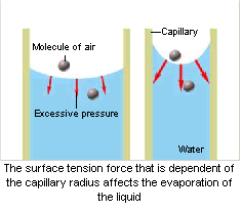

The force interactions between the molecules of a liquid hamper their escape from its surface layer. However, some molecules with sufficient energy do escape. As a result, the liquid evaporates.

In small pores or capillaries, the forces holding the molecules in the liquid are greater because the surface tension is greater. The fluid is attracted to the walls of the tube, which pulls up on the fluid. Gravity pulls down. The resultant stress on the fluid is the surface tension. In small tubes, the liquid molecules are closer to the walls. The fluid is more strongly held up, and the surface tension is higher.

See Also

Example: Porosity measurement

Advantages

The capillary evaporation is an integral part of the steam generation in nature.

Materials

The evaporation rate can vary widely, depending on the ambient pressure and temperature.

A drop of water evaporates for several minutes. The same mass of water in a porous solid with an average capillary radius 1 mm evaporates for several days.

Formula

![]()

uS – rate of evaporation of liquid from cross-section surface of capillary, kg/(m2·s)

C – evaporation constant, kg/(m2·s)

h – relative humidity of vapor

a – ratio of surface area of meniscus to area of capillary

PSo – equilibrium pressure of saturated vapor over smooth surface of liquid, Pa (Pascal)

P – external (atmospheric) pressure, Pa (Pascal)

m – molar mass of liquid (its vapor), kg/mol

s – surface tension of liquid, N/m (Newton/m)

r – radius of curvature of meniscus of liquid in capillary, m

r – density of liquid, kg/m3

T – ambient temperature, K

R – gas constant = 8.31696 J/(mol·K) (Joule/(mol·K))

Notes.

1. In the case of a smooth surface of the liquid a =1(r®¥). In the case of a capillary, the radius of which is close to the curvature radius of a meniscus a = 2.

2. In the case of a relatively narrow capillary the curvature radius of the meniscus r = rk/cos q, where rk – the radius of the capillary, q – the wetting angle.

3. In the case of water C = 1.3·10–2 kg/(m2·s), q = 0 at wetting the glass.

4. PSo is dependent of temperature.

Conditions

A liquid to be evaporated should be in a capillary.

References

Carey, Van P. Liquid-vapor phase-change phenomena: an introduction to the

thermophysics of vaporization and condensation processes in heat transfer

equipment. Washington, D.C.: Hemisphere Pub. Corp., 1992.

Jones, Frank E. Evaporation of water: with emphasis on applications and measurements. Chelsea, Mich.: Lewis Publishers, 1992.